So many little pieces of veneer to edge joint! Out of the 6" wide veneers I cut I only used pieces that around 3" wide due to the color gradation I mentioned earlier. I don't think it's ideal but I'm doing what I see fit with what I have.

Oh tape! I don't know how I got along without it before. Before going to IP the many uses of tape in the shop hardly even crossed my mind. I mean this is real work we were doing right? We don't use

tape! Ha well The right tape for the right job makes things easier. I've used painter's tape for "clamping" the veneer edge joints. It works quite well. The tape has a medium tack... enough to hold on well but not enough to warrant thick sticky adhesives. The tape also is relatively elastic and this is the key. You put the tape on one side of the joint then stretch it over to the other, the "spring-back" in the tape "clamps" the joint! You HAVE to tape both sides for it to work properly... or use weights on one side... but I've found tape on both more to my liking this time around.

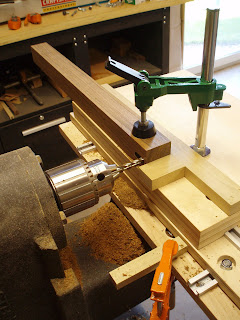

I don't have a vacuum press nor a veneer press yet. but this little clamp up seemed to work well.

Some 8/4 Ash cut, jointed, and planed 3/4" Baltic Birch, framing backer board, and wax paper. You may also notice the blue tape again. Because I don't have a set up where I can get clamps in the center of the "press" I need to compensate. Any wood clamped as such is going to bend so you build up the middle to even it out. There's one layer of blue tape then the wax paper is strategically overlapped to "fare out" the added arc. That doesn't sound like much, well it's the same on top and bottom so each layer is actually two. As the results suggest, it doesn't take much :)

While waiting for the veneering to be done I turned my attention to some hardware as I need to put some mortise in the aprons for them before moving on with the bases.

Hardware is yet another thing that is lacking "these days" (ha I'm not old enough to experience the "old days" but this is what I'm told). Nice simple hardware is hard to come by. Luckily there are nice little knife hinges being made by a couple makers, namely Sanderson Hardware and Brusso. Robert Sanderson is a graduate of CR and makes very nice hardware that can't be found just any where. His hinges are a little more spendy than Brusso's but they are made on a small scale and now Brusso has been stamping their name into the show side of the hinge... I can understand wanting some credit for your work but I really don't want to see branding placed about my work.

I had thought about getting some L/90 degree/corner brackets to simplify and speed things up, alas I don't know if nice little one exist anywhere. Instead of using glue/screw blocks, or buttons I decided to bite the bullet and continue the path of "all out" and make my own brackets.

I say bite the bullet because as I've found I'm not the biggest fan of working with metal in this way. However I'm a bigger fan of making what I want then paying for something I don't like ha.

I went to a local metal supply; they were out of brass bar (sigh shouldn't be a surprise by now) but they had a very small amount of 1/8" brass sheet. They cut me a couple 1" strips free of cut charge though. I knew I didn't want 1" wide brackets but didn't know exactly what size I wanted, also it's probably an odd size which no one carries in bar stock anyway. As is the case I felt 7/8" would be nice and ripped the brass on the band saw with a 6 tpi blade... I would like a finer blade next time. Cross cut on the table saw, then clean up the edges and faces. As long as the metal is non-ferrous you can use many of your wood working machines, though you may want dedicated blades.

Here they are cut, drilled, counter sunk for #4 screws and cleaned to a 400 grit sanding. They aren't completely finished but will only take a couple of minutes to get them where I can work with them. They wont get a final sanding until they are ready to be installed.

These little guys are quite nice in use. Very simple looking, non-obtrusive, a nice matte finish makes the brass relatively warm looking, and they have a nice weight to them physically and visually.

Back to wood yay!

So after trying to cut up the Oak and organize it to steer clear of conflicting prismatics I wasn't completely happy with what I was getting. I decided to go ahead and book match it, well I think I used flipped book matching. The Oak doesn't seem to have an overly strong prismatic difference. I'm sure I'll spot it but I have a feeling it's the "lesser of two evils". It also has some naturally ocurring darker lines which I think people will guess is where the joints are, but they aren't!

Well since I've been working with some moderately less friendly woods I was looking forward to the surface prep on these Oak tops. To my chagrin nasty tear out! Short in length maybe 3/8 or 1/2" long but a good 64th-32nd" deep! In BOTH directions on the same cut of veneer! GAH! While I was working it earlier I thought that this Oak seemed a bit brittle for Oak. It is a darker color that I normally see it, maybe it's an odd plank but it also gives me the impression that it was dried too much... I don't know know, it just feels dry under my tools.

So I'm left scraping the White Oak, it doesn't even scrape that well! So I have to start sanding with 320 grit (hopefully not 220). I knew I was going to have to scrape that Narra, but Oak? come on! Well like I said, next batch is going to include some walnut, cherry, and maple. Hopefully there will be less surprises heh.